Industrial Robotics Solutions

Specialists of our company have great experience in the development and implementation of «turnkey» solutions based on industrial robots ABB and Kuka.

Based on a thorough analysis of Customer’s production processes our engineers prepare a feasibility report of the suitability for using industrial robots in the process.

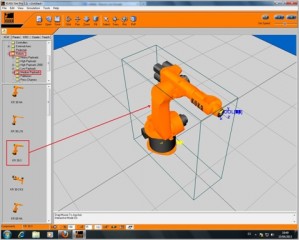

On the next step our engineers simulate a concept solution realized in special engineering software.

It gives a complete picture of concept process layout to Customer. Also it confirms the functionality and efficiency of the proposed concept.

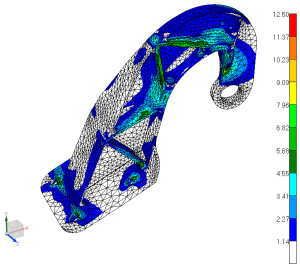

Preliminary estimation of static and dynamic loads provides the correct choice of robot type and model and carrying structure of tooling.

FEM strength analysis of tooling equipment at design phase allows to identify all dangerous areas in construction. It provides a sufficient safety rate and minimum weight design. All of these especially important for complex grippers installed directly on the robot wrist.

Pre-assembling of complete robotic cell in AdvanSystems Workshop allows to minimize installation time on site and as a result, save time and money for our customers. Demonstration of complete cell at this project phase makes our customers confident in functionality and readiness of the system to shipment.

Installation and commissioning of robotic systems is carried out by qualified personnel which has great experience in successful installations for food, automotive, aerospace and many other manufacturing industries.

Close collaboration between our engineers and Customer’s operating staff during commissioning phase provides the most effective and safe using of the new system from early beginning.